34 Mitsui’s Cash Cow

Miike Coal Mine at the Time of Privatization

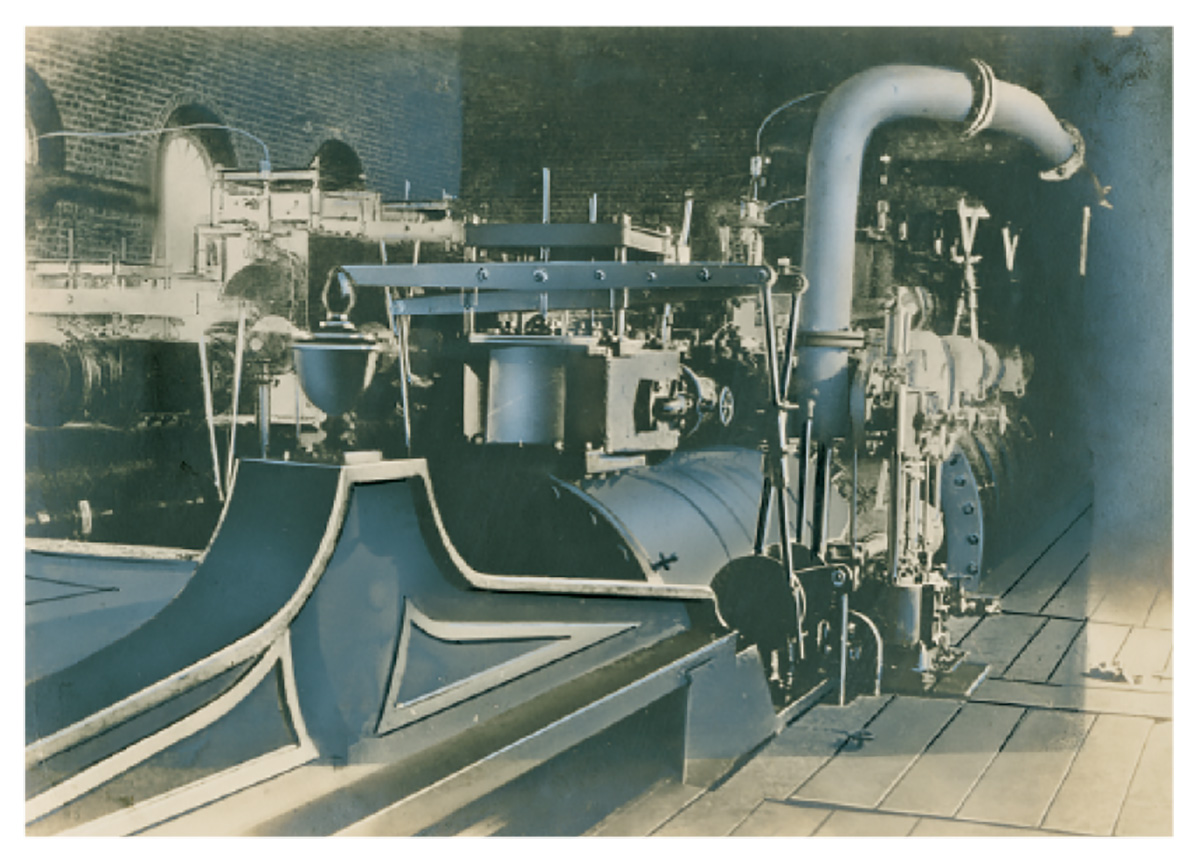

In July 1889, when the Miike Coal Mine was sold off, a major earthquake struck the Kyushu region. Combined with continuous heavy rain, the Kattachi Pit, which had been under development since the government-operated period, was flooded along with numerous pumps. Dan Takuma began Mitsui’s management of the mine under these difficult conditions. The greatest challenge was figuring out how to solve the problem of the vast volume of groundwater that plagued the Miike Mine. This was particularly true of the pre-flood Kattachi Pit, which had once recorded an inundation of about 10 tons of water per minute. Dan become convinced that what was needed was a Davey Pump (→Fig. 34b), which they had seen for themselves in England during the government-operated era.

Revival of the Kattachi Pit

To restore the Kattachi Pit, Dan, who had decided to deploy the latest pump technology, went to Tokyo with a budget proposal for 500,000 yen-about one-tenth of the price at which the Miike Mine had been sold-along with his resignation letter, to persuade the top executives at Mitsui. The Davey Pump was a large, powerful pump capable of drawing water up from above ground, with the advantage that there was no risk of the pump itself being submerged. Dan explained to Masuda Takashi and the others that if pumping was successful, they could recover their submerged machinery, and even if it failed, the pump could be used elsewhere, so the loss would be limited to no more than 80,000 yen, or the cost of the pump’s installation and related excavation costs. As a result, his enormous budget proposal was approved and a telegram immediately sent out for the pump’s purchase. Of this course of events Dan later said, “This was when I first realized that I was no longer just an engineer, but had become the manager of a business.” In July 1892, two pumps were delivered to Omuta, and by October of the following year, they had successfully pumped all of the water from the pit. Subsequently, Davey pumps were deployed to other pits, and came to have a groundbreaking significance for the Miike Mine, which had been plagued by severe groundwater issues.

Expansion to Chikuho and Hokkaido

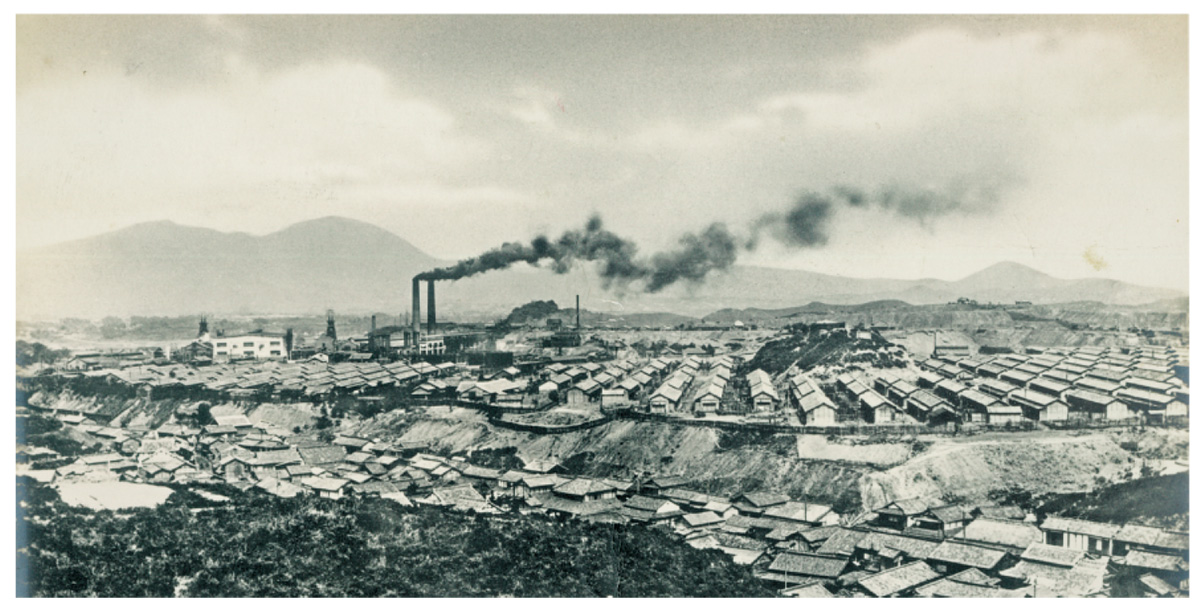

As coal mining got back on track at the Kattachi Pit, a series of new pits were developed at the Miike Coal Mine, including Miyanohara and Manda. In its 10th year of operation, the Manda Pit, where digging had reached a coal seam at a depth of about 270 meters in 1902, was producing more than 800,000 tons per year and had grown to become one of the mine’s mainstay pits. Meanwhile, as development continued at Miike, Mitsui Mining, which had been reorganized as a partnership, expanded into the Chikuho region of northern Kyushu. In 1900, it moved ahead with the acquisition of mining areas in the Kaho and Tagawa counties, establishing the Yamano and Tagawa coal mines (which later became the Yamano mining works and the Tagawa mining works (→Fig. 34d). In the 1910s, they extended their reach to mining areas in Hokkaido, later beginning full-scale coal mining operations in Noborikawa (Yubari) and Sunagawa.

“Mitsui’s Cash Cow”

Mitsui Mining thus secured a number of excellent mining areas, which by the beginning of the 20th century represented about 15% of all mining areas in Japan and about 19% of all coal output. Among them, the Miike Coal Mine produced the greatest volume, with over 60% of all coal mined by Mitsui Mining coming from the Miike Mine. Further, as of 1909, profits from the Miike Coal Mine alone amounted to approximately 2,450,000 yen, accounting for 80% of Mitsui Mining’s total profits of about 3,000,000 yen and over 30% of the combined profits of Mitsui Bank, Mitsui Bussan, and Mitsui Mining. The Miike Mine would have a very large role to play as “Mitsui’s cash cow.”

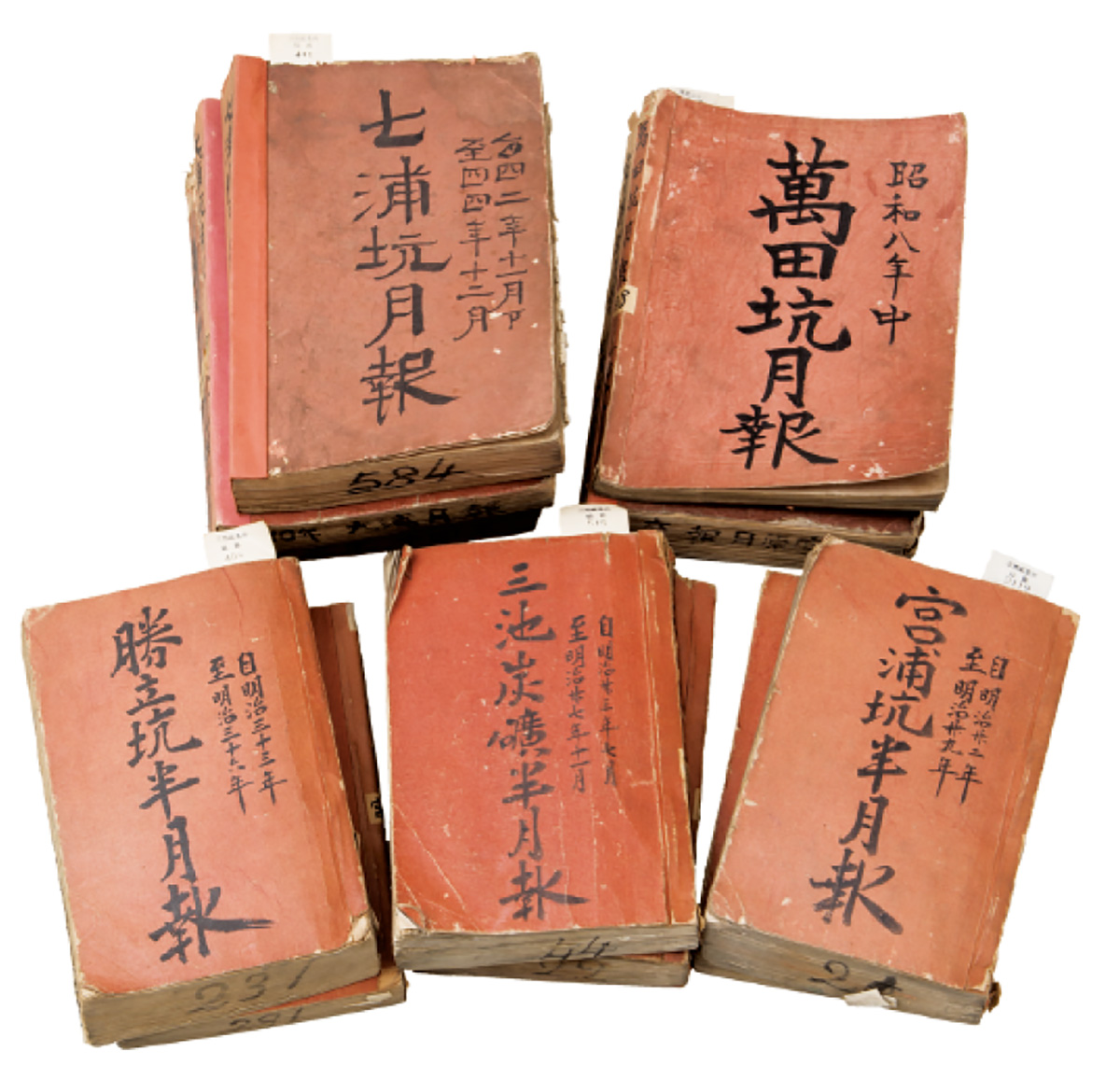

At the Miike Coal Mine, semimonthly or monthly reports were prepared for each pit, including Nanaura, Kattachi, Miyaura, Manda and others. The Miike Coal Mine Semimonthly (or monthly) Bulletin is assumed to be a compilation of these other reports. It not only describes excavation, mining and drainage conditions at each pit, but includes details of coal market conditions and coke production.

Taken from the Miike Coal Mine Semimonthly Bulletin issued from July 1890 through November 1894, this clipping (→translation) is the report from the first half of March 1894. The report vividly conveys the hardships faced at the Kattachi Pit, which was at risk of being flooded, as they finally succeeded in reaching the coal seam. The revival of the Kattachi Pit not only raised Dan Takuma’s reputation as a business manager, but represented the starting point for the development of Miike Coal Mine as “Mitsui’s cash cow.”

Translation

The project to open the Kattachi Pit is proceeding well, and as we have already reported, we reached the coal seam at 6 a.m. on March 4, at a depth of about 121 meters from the mouth of the pit. Water volume has declined, and the average extraction rate is about seven tons per minute. The coal seam, about 2.4 meters thick, appears to be of high quality.

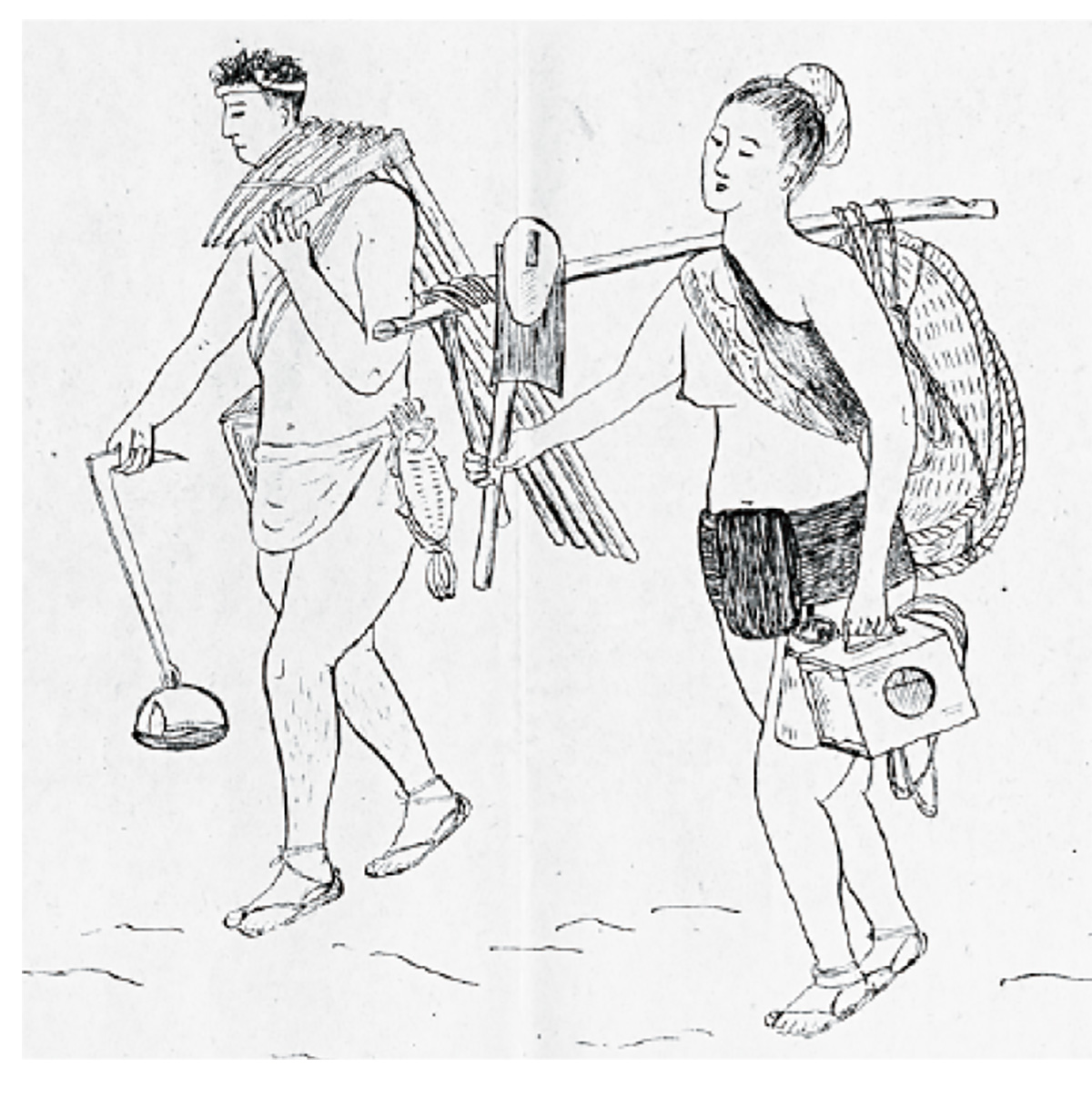

Description

Development of the Kattachi Pit was delayed due to the groundwater problem, and at one point it was close to flooding. The person who restored was Dan Takuma, who had studied the latest pump technology in England during the mine’s government-operated era, and who later became head of the Miike Coal Mine.

This illustration was included in the History of the Miike Mining Works, (1942), compiled by Mitsui Mining for the purpose of creating a company history.

The Tagawa Ita Pit made famous in a Tanko Bushi, or coal-mining folk song. Two chimneys can be seen at center left, the same ones sung about in the lyrics, “The chimneys are so tall, even the moon must find it smoky.” These two chimneys, along with the approximately 360-meter-deep shaft turret (slightly to the left of the chimneys) remain standing today as symbols of Tagawa.